Product Introduction:

Thyristor reversing electroplating rectifier and silicon controlled reversing electroplating rectifier are usually defined to be synonymous. It adopts 6-pulse or 12-pulse SCR automatic reversing rectifier. It is mainly used as all kinds of metal and nonmetal surface electroplating reversing rectification power supplies, such as electroplating hard chrome and electrolytic oil-removal. The silicon controlled reversing electroplating rectifier includes high-power electrolytic power supply, plating power supply, electrical heating rectifier power supply and military high stability power supply. This reversing rectifier also includes intermediate frequency inverter power supply, special high-voltage rectifier power supply, PLC microcomputer automatic control system and special transformer, etc.

Parameters of Silicon Controlled Reversing Electroplating Rectifier:

1. Power Supply: 3P AC380V, 400V, 450V, etc. frequency (50Hz)

2. Rated Output DC Voltage: 12V, 15V, 18V, 24V, 36V, any voltage specification

3. Rated Output DC Current: 500A, 1000A, 1500A, 2000A, 3000A, 4000A, 5000A, 6000A, 8000A, 12000A, 15000A, 18000A, 20000A, any current specification

4. Soft Start Working Time: 0-200s

5. Constant Current and Constant Voltage Control Accuracy: ≤±1%

6. Output Ripple Coefficient of 6-Pulse Rectifier: ≤5%

Output Ripple Coefficient of 12-Pulse Rectifier: ≤3%

7. Asymmetry Degree of Trigger Pulse: ≤0.1°

8. Pulse Phase-Shifting Resolution: ≤1μs

Features of Silicon Controlled Reversing Rectifier:

1. Silicon controlled reversing electroplating rectifiers provide local and remote operation modes.

2. Constant current and constant voltage control modes are optional for customers.

3. This type of SCR rectifier adopts contactless output reversing mode. It has one-off reversing and automatic periodic reversing.

4. This reversing rectifier uses SCR phase-shifting voltage for regulation and rectification.

5. Rectification transformer adopts three-core five-column structure. The iron core uses good oriented silicon steel sheets and the transformer coils are winded by full copper wires. The no-load loss of this silicon controlled reversing electroplating rectifier is less than 2%, saving 8% to 10% electricity than common three-phase three column rectification transformers.

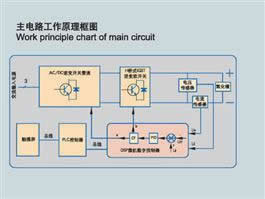

6. Thyristor reversing rectifiers adopt DSP microcomputer digital trigger control.

7. Remote control operation boxes can be chosen according to customer's requirements.

Lantytk® Corp is a professional manufacturer and supplier of silicon controlled reversing electroplating rectifiers in China. In addition to this type of reversing rectifier, we also produce thyristor electrolytic rectifiers and SCR electroplating rectifiers. Our products have been exported to USA, Germany, Australia, Singapore, India, Brazil, Iran, Vietnam, Kazakhstan and Malaysia, etc.