Description:

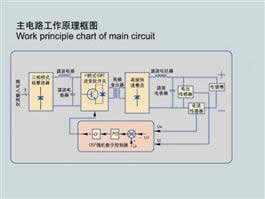

This pulse power supply adopts IGBT switch rectifier, PWM chopper technology, DSP microcomputer digital control technology and touch screen operation system. The pulse electroplating power supply has the controlling functions of single DC pulse, double DC pulse automatic constant current and automatic constant voltage. Pulse amplitude is continuous and adjustable, pulse duty ratio and frequency can also be adjusted. The pulse power supply provides a good human-computer interface with a nice visibility. The pulse electroplating power supply can store and record various real-time process curves automatically, such as electroplating current, voltage and bath temperature. It can also store and invoke multiple sets of process parameters. With high automation, this pulse power supply can greatly improve the smoothness, compactness and corrosion resistance of electroplating film layer. The pulse electroplating power supply can also lower porosity, eliminate hydrogen embrittlement, improve the quality of products' electroplating layer and save a lot of rare metals. It is extensively used in those enterprises like aviation, aerospace, weapon and ship, etc. This pulse power supply is also used as pulse electroplating rectifier power supply of electroplating gold, silver, palladium, titanium and other precious metals in scientific research institute.

Main Technical Parameters of Pulse Electroplating Power Supply:

|

Pulse Power Supply

|

3P AC380V, 400V, 450V, etc. frequency (50Hz)

|

|

Rated Output Voltage

|

6V, 12V, 15V, 18V, 24V, 36V, any voltage specification

|

|

Rated Output Current

|

500mA, 1000mA, 2000mA, 5000mA, 10A, 20A, 50A, 100A, 200A, 300A, 500A, 1000A, 1500A, 2000A, 3000A, any current specification

|

|

Soft Start Working Time

|

0 to 200s

|

|

Control Accuracy

|

≤±1%

|

|

Pulse Pace Frequency Range

|

1000 to 8000HZ

|

|

Operation Mode

|

local or remote operation mode

|

|

Output Control Mode

|

unidirectional or bidirectional pulse output control

|

|

Output Constant Control Mode

|

constant current or constant voltage control mode

|

|

Pulse Phase-Shifting Resolution

|

≤1μs

|

Features of Pulse Electroplating Power Supply:

1. This pulse power supply can store or invoke 5 sets of process parameters, which can shorten the machining and programming time.

2. Remote control operation box can be chosen according to customer's situation on site.

3. Pulse electroplating power supply can record technological parameters and real-time process curves of forward and reverse current or voltage, pulse current or voltage magnitude, pulse duty ratio, pulse frequency, anodizing time and bath temperature, etc.

4. The pulse power supply can provide CAN BUS, PROFIBUS, ETHERNET, RS485 and RS232 fiber communication to realize remote control or monitoring.

5. The quality of electroplating layer is obviously superior to common electroplating process, especially in compactness, smoothness and corrosion resistance.

6. Pulse electroplating power supply can be connected with computer through RS485 communication interface, or can be stored by U disk then re-stored to computer. It is convenient to save customers' files and to analyze the process quality of anodizing parts.

7. This pulse power supply has several protection functions: openphase, overvoltage, under voltage, quick fuse or fuse alarm protections of AC power supply, output over current and current limiting protections, output short circuit and instantaneous overload protections, IGBT RFSM, quick rectifier diode components, switch rectifier transformer and bus copper bar overheat, fan overheating or excess water pressure and low block trigger pulse protections.

Lantytk® Corp is a professional manufacturer and supplier of pulse electroplating power supply in China. In addition to this pulse power supply, we also produce silicon controlled rectifier, silicon controlled reversing and inverter soft switch electroplating power supplies. Our products have been exported to USA, Germany, Australia, Singapore, India, Brazil, Iran, Vietnam, Kazakhstan and Malaysia, etc.